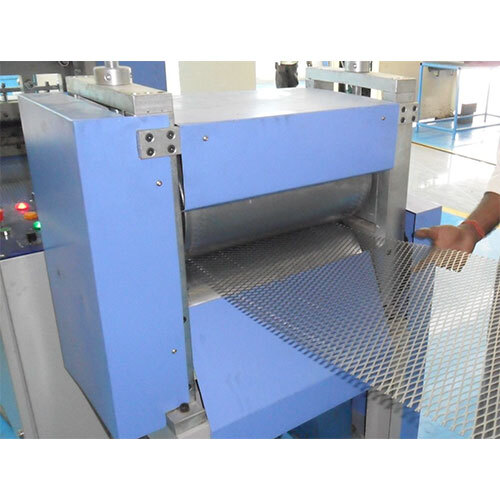

AUTOMATIC WIRE BENDING MACHINE

Product Details:

- Machine Type AUTOMATIC WIRE BENDING MACHINE

- Voltage 220 Volt (v)

- Frequency 50 Hertz (HZ)

- Control System Fully Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Click to View more

AUTOMATIC WIRE BENDING MACHINE Price And Quantity

- 1 Piece

- 500000.0 INR/Piece

AUTOMATIC WIRE BENDING MACHINE Product Specifications

- 1 Year

- Grey

- Automatic

- Painted

- Industrial

- Electricity

- 50 Hertz (HZ)

- Fully Automatic

- 220 Volt (v)

- AUTOMATIC WIRE BENDING MACHINE

AUTOMATIC WIRE BENDING MACHINE Trade Information

- GURUGRAM

- 10 Piece Per Month

- 7 Days

- Contact us for information regarding our sample policy

Product Description

An automatic wire bending machine is a piece of equipment designed to bend wire into specific shapes and angles automatically, typically for mass production. These machines are used in a wide range of industries, including automotive, electronics, construction, and jewelry making. They are especially valuable for producing complex wire forms with high precision and efficiency.

Key Features and Components of an Automatic Wire Bending Machine:

-

Wire Feeding Mechanism:

- The machine automatically feeds wire from a spool into the bending area, ensuring consistent wire length and alignment for each part being produced.

-

Bending Tool/Die:

- The bending tool (or die) is the part that forms the wire into the desired shape. It typically consists of multiple bending points, rollers, and molds that guide the wire during the bending process.

-

CNC Controller:

- The machine is often controlled by a CNC (Computer Numerical Control) system, which allows for precise control of the bending angles, wire lengths, and the number of bends. This makes it easy to change designs and replicate complex shapes.

-

Rotating or Linear Axis:

- Most automatic wire bending machines have a rotating axis or linear axis that moves the wire through various bending stations to achieve the desired shape.

-

Cutting Mechanism:

- In some machines, there is an integrated cutting system that trims the wire to the correct length after it has been bent.

-

Safety Features:

- Since bending machines can handle high tension and force, they are equipped with various safety features, such as emergency stop buttons, guards, and sensors.

Types of Bending:

- Right Angle Bends: Creating bends at specific angles (90).

- Coils and Springs: Bending wire into spiral or helical shapes.

- Curves: For more complex shapes, like arcs or circular forms.

Benefits of an Automatic Wire Bending Machine:

- Efficiency: The machine can produce a large volume of bent wire parts in a short amount of time, which increases production efficiency.

- Precision: CNC-controlled machines provide highly accurate bends, ensuring consistent quality across all parts.

- Reduced Labor Costs: Automating the bending process reduces the need for manual labor, saving time and costs.

- Flexibility: It allows for quick changes in design, making it suitable for batch production or custom orders.

- Improved Safety: By automating the process, workers are less exposed to the risks associated with manual wire bending.

Applications:

- Automotive Industry: For making wire components like brackets, springs, or frames.

- Electronics: Creating wire forms for circuit boards or connectors.

- Furniture Manufacturing: Bending wire to create frames for chairs, tables, or racks.

- Construction: Making wire reinforcements or mesh for concrete reinforcement.

- Jewelry: Bending wire to create intricate jewelry designs like rings, bracelets, and chains.

Automatic wire bending machines are crucial for mass production environments where both precision and efficiency are essential. Would you like to know more about specific models or how they work in different industries?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese