Media,Mesh & expanded mesh stitching machine

500000.0 INR/Piece

Product Details:

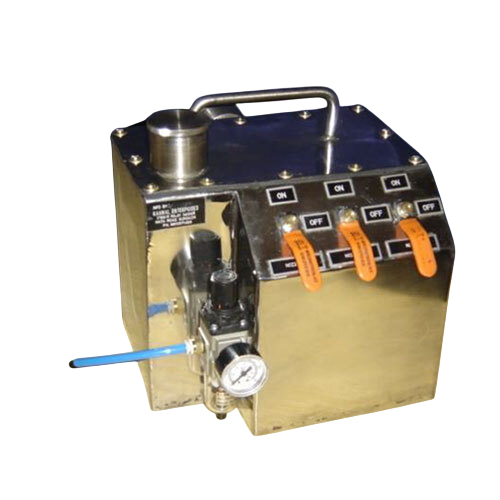

- Machine Type Media,Mesh & expanded mesh stitching machine

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Color Green

- Warranty 12 Months

- Click to View more

X

Media,Mesh & expanded mesh stitching machine Price And Quantity

- 500000.0 INR/Piece

- 1 Piece

Media,Mesh & expanded mesh stitching machine Product Specifications

- Electricity

- Industrial

- Media,Mesh & expanded mesh stitching machine

- 220 Volt (v)

- Green

- 12 Months

- Automatic

- Semi-Automatic

Media,Mesh & expanded mesh stitching machine Trade Information

- GURUGRAM

- Cash Advance (CA) Cash in Advance (CID)

- 50 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- All India

Product Description

A Media Mesh & Expanded Mesh Stitching Machine is a specialized piece of equipment used in the production of various mesh types, typically for industrial, architectural, or security applications. Heres a breakdown of its function:

Purpose:

The machine is designed for stitching together expanded metal mesh or media mesh sheets, which are often used for applications such as fencing, reinforcement, security barriers, or decorative features. It uses a stitching process to create a durable, functional connection between metal pieces, enhancing the structural integrity of the mesh.

Key Features:

Mesh Stitching: The machine uses advanced stitching techniques (such as sewing or welding) to combine individual metal strands or sheets, creating a cohesive mesh structure.

Material Compatibility: Typically works with materials like steel, aluminum, or other metals used in mesh construction.

Customization: The machine can stitch meshes of different sizes, shapes, and hole patterns, allowing for flexibility depending on the application.

Automation: Many models are automated to improve speed and precision, with adjustable settings for tension, stitching length, and mesh dimensions.

Efficiency: It enhances the speed and quality of mesh production compared to manual methods, ensuring consistent results across large production runs.

Applications:

Security Fencing: Used to create secure barriers for properties, airports, military installations, etc.

Reinforcement Mesh: For construction and building reinforcement in concrete.

Industrial Mesh: For filtering, screening, or separating materials in various industrial applications.

In short, the Media Mesh & Expanded Mesh Stitching Machine helps automate the stitching or joining of metal mesh materials for a wide range of practical applications, ensuring strength, durability, and consistency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese