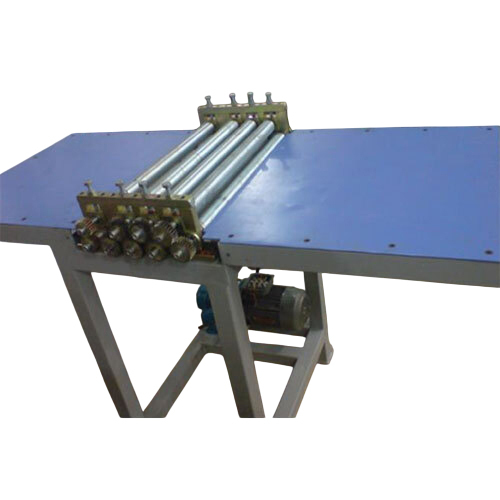

Mini Perforation machine

68000.0 INR/Piece

Product Details:

- Control System Semi-Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

X

Mini Perforation machine Price And Quantity

- 1 Piece

- 68000.0 INR/Piece

Mini Perforation machine Product Specifications

- Electricity

- 12 Months

- Semi Automatic

- Painted

- Industrial

- 220 Volt (v)

- Semi-Automatic

Mini Perforation machine Trade Information

- GURUGRAM

- Cash Advance (CA)

- 10 Piece Per Month

- 1 Week

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

A Mini Perforation Machine is a compact, specialized machine designed for creating small, precise perforations (holes or slits) in various materials such as paper, plastic, metal, or fabric. These machines are commonly used in industries that require perforated products for applications like packaging, printing, or decorative designs.

How a Mini Perforation Machine Works:

-

Perforation Process:

- The machine uses a sharp, rotating punching tool or die to create a series of holes or slits in the material.

- The material passes through a set of rollers, and the perforation tool creates holes in a regular pattern.

- These holes could be circular, square, or any other shape depending on the specific die used.

-

Adjustable Settings:

- Hole Size: Many mini perforation machines allow for the adjustment of the size of the holes.

- Hole Spacing: The distance between the perforations can be adjusted for different applications.

- Speed: Some models feature adjustable speed settings, enabling faster or slower perforation based on the material being processed.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese