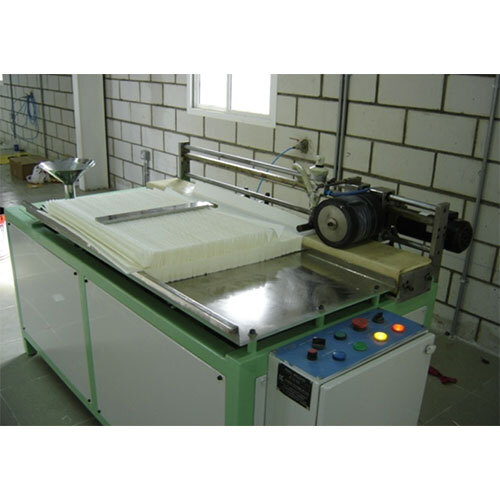

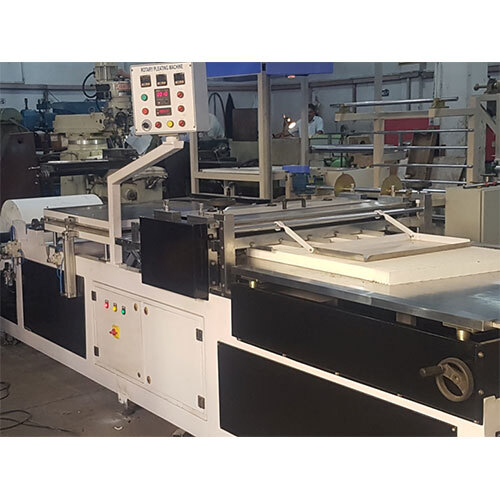

PU CURING TURN TABLE

100000.0 INR/Piece

Product Details:

- Control System Semi-Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Color White

- Warranty 12 Months

- Click to View more

X

PU CURING TURN TABLE Price And Quantity

- 100000.0 INR/Piece

- 1 Piece

PU CURING TURN TABLE Product Specifications

- White

- 220 Volt (v)

- Semi-Automatic

- Electricity

- Automatic

- 12 Months

PU CURING TURN TABLE Trade Information

- GURUGRAM

- Cash Advance (CA)

- 50 Piece Per Week

- 01 Week

- No

- Contact us for information regarding our sample policy

- South America Asia Central America Australia North America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

A PU (Polyurethane) Curing Turntable is an industrial equipment used in the production and curing of polyurethane products. It is designed to rotate items placed on it to ensure even curing or heat treatment during the polyurethane application process. These turntables are typically used in manufacturing industries where PU materials are used, such as in foam production, coatings, or molded parts.

Key Features and Description of a PU Curing Turntable:

Rotating Platform:

The turntable has a rotating platform that holds the PU-coated items. The rotation ensures uniform exposure to heat or curing agents for consistent results. This is important for applications where even curing is essential for product quality.

Adjustable Speed:

The rotation speed can usually be adjusted to match the curing process requirements. Faster rotations might be required for quick curing, while slower rotations could be used for more precise applications.

Heat Resistance:

Made of materials resistant to high temperatures and chemicals, ensuring it can withstand the heat required for curing PU materials without warping or degrading.

Automated or Manual Operation:

It can either be manually operated or automated. In automated systems, the turntable is integrated into the production line, where items are placed on it and automatically rotated during the curing process.

Temperature Control:

Often designed to work in conjunction with ovens, UV light, or other curing technologies that provide controlled temperature or light to cure the polyurethane evenly.

Durability:

Constructed with robust materials such as stainless steel or high-quality plastics that can handle long-term use in industrial environments without failure.

Size Variability:

Available in different sizes, allowing for small to large items to be placed on the turntable depending on production needs.

Easy Loading and Unloading:

Designed for easy loading and unloading of items, whether manually or with robotic systems.

Uses in Production:

PU Foam Manufacturing: Used for curing polyurethane foams, ensuring the foam achieves the desired consistency and strength.

Molded Parts: In the production of molded polyurethane parts, the turntable ensures uniform curing, reducing the risk of inconsistencies in the final product.

Coating or Laminating: Can be used for coating items with polyurethane for a protective layer, ensuring the coating cures evenly.

Benefits:

Improved Efficiency: The continuous rotation ensures faster and more consistent curing, improving overall production efficiency.

Enhanced Quality: Ensures that every product undergoes the same curing process, leading to higher quality and fewer defects.

Time Savings: Automating the curing process with a turntable reduces manual intervention, saving time and labor costs.

In summary, a PU Curing Turntable is essential for ensuring uniform curing in the production of polyurethane-based products. By offering efficient and consistent rotation, it enhances productivity and product quality in industries where PU materials are used.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese