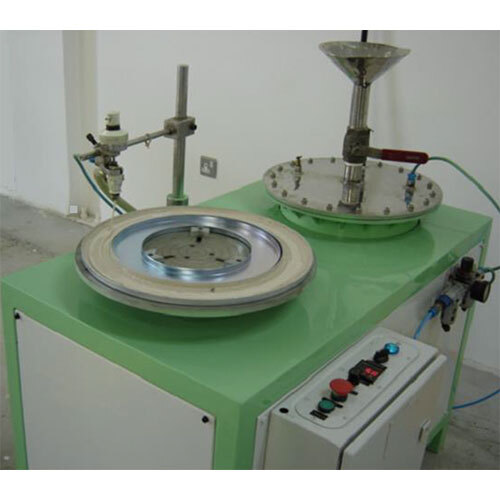

PVC ADHESIVE DISPENSER MACHINE

Product Details:

- Machine Type PVC ADHESIVE DISPENSER MACHINE

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Green

- Click to View more

PVC ADHESIVE DISPENSER MACHINE Price And Quantity

- 1 Piece

- 500000 INR/Piece

PVC ADHESIVE DISPENSER MACHINE Product Specifications

- 1 Year

- Green

- Semi-Automatic

- Automatic

- PVC ADHESIVE DISPENSER MACHINE

- 220 Volt (v)

- Electricity

- Industrial

- Painted

PVC ADHESIVE DISPENSER MACHINE Trade Information

- GURUGRAM

- Cash Advance (CA)

- 2-3 Piece Per Day

- 1 Days

- No

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

A Gas Turbine Filter Machinery is a specialized system used to filter and clean the air entering gas turbines, ensuring that the turbine operates efficiently and reliably. Gas turbines are widely used in power plants, aviation, and industrial applications, where they rely on a constant supply of clean air for combustion and operation. The quality of air entering a turbine can significantly impact its performance, fuel efficiency, and lifespan. Therefore, filtration is a crucial component to protect the turbine from contaminants such as dust, dirt, moisture, and other particulates that could cause damage or reduce efficiency.

Components and Functions of Gas Turbine Filter Machinery:

-

Pre-filters:

- Pre-filters are the first line of defense against large particles such as dust, sand, and larger debris. These filters remove coarse particles before the air reaches finer filtration stages, ensuring that the turbine's internal components are protected from large contaminations that could cause mechanical wear or failure.

-

High-Efficiency Filters (HEPA or ULPA):

- Gas turbines often require high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filters to capture very fine particles, including soot, microorganisms, and other fine contaminants. These filters are designed to capture particles as small as 0.3 microns or even smaller, providing the high level of cleanliness required for optimal turbine performance.

- HEPA filters ensure that no particles enter the turbine that could damage components like blades, fuel injectors, or combustion chambers.

-

Carbon Filters (Optional):

- Some turbine applications, particularly those in urban or industrial areas, may require carbon or activated carbon filters. These filters are designed to remove chemical contaminants such as gases, fumes, and odors from the air before it enters the turbine, preventing corrosion and damage caused by chemical reactions.

-

Air Dryers (Optional):

- In some cases, air entering the gas turbine must be dried to prevent moisture buildup, which can lead to corrosion, inefficiency, or damage to the turbine components. Air dryers can be integrated into the filtration system to reduce the moisture content of the air before it enters the turbine.

-

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese