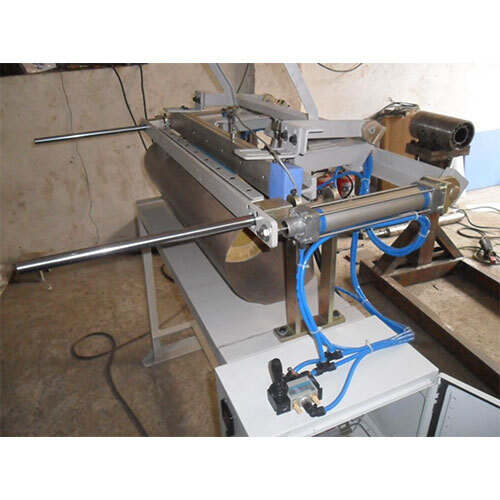

SPOT WELDING M-C

Product Details:

- Technology Laser

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Usage & Applications Industrial

- Click to View more

SPOT WELDING M-C Price And Quantity

- 1 Piece

- 500000.0 INR/Piece

SPOT WELDING M-C Product Specifications

- Laser

- Industrial

- Semi Automatic

- Electricity

- Painted

SPOT WELDING M-C Trade Information

- 10 Piece Per Day

- 1-4 Days

- All India

Product Description

A Spot Welding Machine (M-C) refers to a type of welding equipment designed for joining two metal workpieces together by applying heat and pressure to a small spot on the surface. Spot welding is commonly used in industrial applications where a fast and efficient method is required to bond thin metal sheets.

The "M-C" in your query likely refers to a specific model or series of the spot welding machine, possibly from a particular manufacturer or technology (e.g., "M-C" could stand for "Model-C," "Machine-C," or something similar). However, the core function and design of a spot welding machine remain largely consistent across different brands and models.

How Spot Welding Works:

-

Heat Generation: In spot welding, electrical resistance is used to generate heat. A high current is passed through the workpieces between two copper electrodes. The current flows through the metal, and due to the electrical resistance, heat is generated at the point where the electrodes meet the workpieces.

-

Pressure: The copper electrodes are pressed against the metal pieces, creating a localized heating effect. This heat melts the metal at the contact points, creating a small molten pool. Once the heat source is removed, the molten metal cools and solidifies, forming a "spot weld" that joins the two metal sheets.

-

Cooling: After the heat is applied, the weld is quickly cooled by the pressure of the electrodes, which solidifies the joint and ensures a strong bond.

Key Components of a Spot Welding Machine (M-C):

-

Electrodes: These are typically made of copper and are responsible for transferring the electrical current to the workpieces. The electrodes must be durable and able to withstand high temperatures.

-

Transformer: It steps down the electrical current to the correct level suitable for the welding process. The transformer adjusts the voltage and current used in the welding process to match the materials being welded.

-

Control System: The spot welding machine includes a control system that regulates the current, duration of the welding cycle, and pressure applied. The settings can often be adjusted based on the thickness of the materials and the desired strength of the weld.

-

Pressure Mechanism: The machine applies pressure to the workpieces through the electrodes to hold them together during the welding process. The pressure ensures a consistent and uniform bond.

-

Cooling System: Spot welding generates significant heat, so the machine often includes a cooling system (such as water-cooled electrodes) to prevent overheating and ensure consistent performance.

Applications of Spot Welding Machines:

-

Automotive Manufacturing: Spot welding is widely used in the automotive industry to join thin sheets of metal, such as in the construction of car bodies. The process is fast and efficient for assembling large numbers of components.

-

Sheet Metal Fabrication: It is commonly used in industries where thin sheets of metal need to be welded together, such as in the production of appliances, HVAC systems, and electrical enclosures.

-

Electronics: In the electronics industry, spot welding is used for creating small, precise welds, such as connecting battery tabs in battery packs.

-

Aerospace and Heavy Equipment: Spot welding is used to join metals in high-strength, high-reliability applications where welding needs to be both fast and consistent.

Advantages of Spot Welding:

-

Speed: Spot welding is a fast process, ideal for mass production settings where high throughput is essential.

-

Strength: When done properly, spot welding creates strong, durable welds, often as strong as or stronger than the base materials being welded.

-

Automation: Spot welding machines are highly automatable, making them ideal for integration into automated production lines for industries like automotive manufacturing.

-

Minimal Heat Affected Zone: Since the heat is localized to the spot where the electrodes meet, there is little to no heat-affected zone (HAZ), reducing the risk of distortion in the surrounding material.

Types of Spot Welding Machines:

-

Manual Spot Welding Machine: Requires an operator to manually place the workpieces between the electrodes and activate the welding process. These machines are often used for smaller production runs or for precise, localized welding.

-

Automatic Spot Welding Machine: These machines are automated, often integrated with robotic arms, for high-volume production. They automatically position the workpieces, apply welding, and sometimes even handle the removal of the welded parts.

-

Pneumatic or Hydraulic Spot Welding Machines: These machines use pneumatic or hydraulic pressure to apply force during the welding process. They are often used in heavier applications where greater pressure is needed for the weld.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese