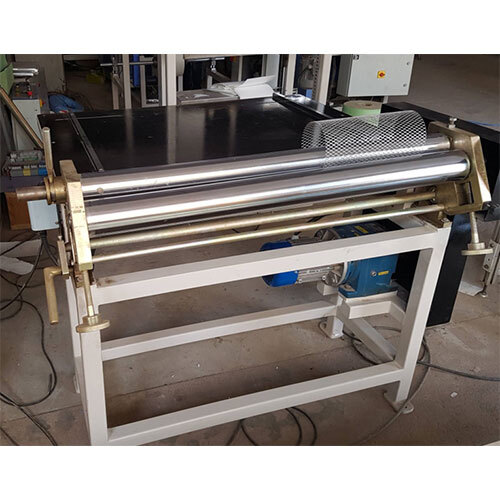

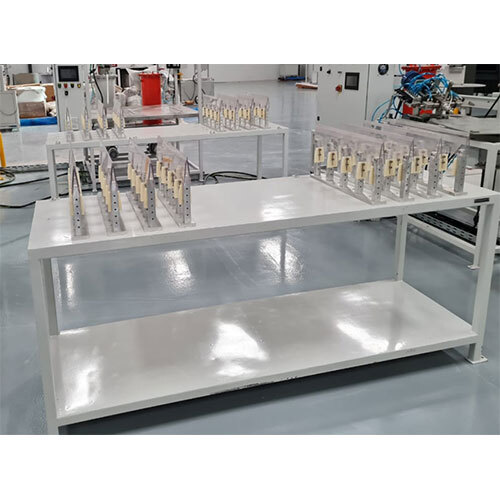

X-Y COORDINATE PU DISPENSING MACHINE

500000.0 INR/Piece

Product Details:

- Machine Type X-Y COORDINATE PU DISPENSING MACHINE

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty 12 Months

- Click to View more

X

X-Y COORDINATE PU DISPENSING MACHINE Price And Quantity

- 1 Piece

- 500000.0 INR/Piece

X-Y COORDINATE PU DISPENSING MACHINE Product Specifications

- Electricity

- 12 Months

- Industrial

- Painted

- Automatic

- Semi-Automatic

- 220 Volt (v)

- X-Y COORDINATE PU DISPENSING MACHINE

X-Y COORDINATE PU DISPENSING MACHINE Trade Information

- GURUGRAM

- Cash Advance (CA)

- 01 Piece Per Week

- 1 Week

- No

- Asia

- All India

Product Description

An X-Y Coordinate PU Dispensing Machine is a precision system used for dispensing polyurethane (PU) or other types of adhesives, sealants, and materials in a controlled and accurate manner. The "X-Y" refers to the machine's ability to move the dispensing nozzle in two directionshorizontal (X-axis) and vertical (Y-axis)allowing it to apply material with high precision over a specified area or pattern.

Key Features of an X-Y Coordinate PU Dispensing Machine:

High Precision: The machine uses a precise coordinate system to control the position of the dispensing nozzle. This allows for accurate dispensing of PU or other materials, even in complex or intricate patterns, without over-application or wastage.

Automated Operation: The X-Y Coordinate system allows for automated material dispensing, significantly improving production speed and consistency while reducing the need for manual intervention.

Versatility: The machine can be used for various applications such as sealing, bonding, coating, or gasketing, and it can handle different types of materials like adhesives, silicones, and urethanes, making it suitable for a wide range of industries (automotive, electronics, packaging, etc.).

Adjustable Settings: The machine can be adjusted to handle varying material viscosities, ensuring optimal dispensing speed and material flow for different types of PU and other fluids.

Customization: Many X-Y Coordinate PU Dispensing Machines come with customizable dispensing patterns, allowing users to program specific routes or shapes for the material application, depending on the part or product being processed.

Controlled Dispensing: The system often includes features like temperature control, pressure regulation, and flow control to ensure the right amount of PU material is dispensed consistently, improving product quality and reducing material waste.

Touchscreen Interface: These machines typically feature user-friendly control panels or touchscreen interfaces, making it easy to program dispensing parameters, monitor progress, and adjust settings on the fly.

Benefits for Kanwal Enterprise:

Increased Precision and Accuracy: The X-Y coordinate system ensures exact placement of PU material, reducing errors and improving the quality of the final product.

Higher Efficiency: Automation allows for faster dispensing and less downtime, which can increase overall production rates.

Material Cost Savings: With precise dispensing, material waste is minimized, helping to reduce costs and maximize the usage of expensive adhesives or sealants.

Flexibility: The ability to handle various dispensing patterns and materials means the machine can be adapted for different product types and manufacturing requirements.

In summary, an X-Y Coordinate PU Dispensing Machine would provide Kanwal Enterprise with a highly efficient, precise, and cost-effective solution for dispensing polyurethane materials, improving product quality and optimizing production processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese