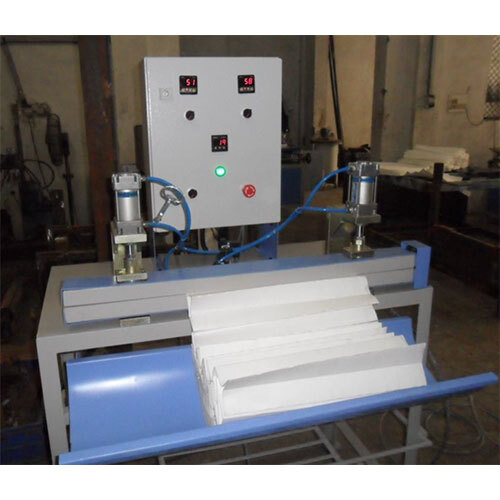

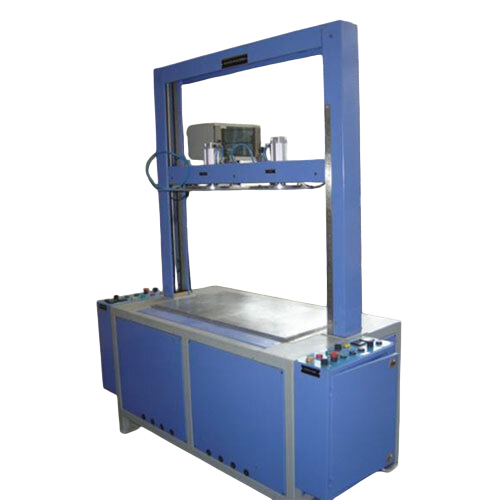

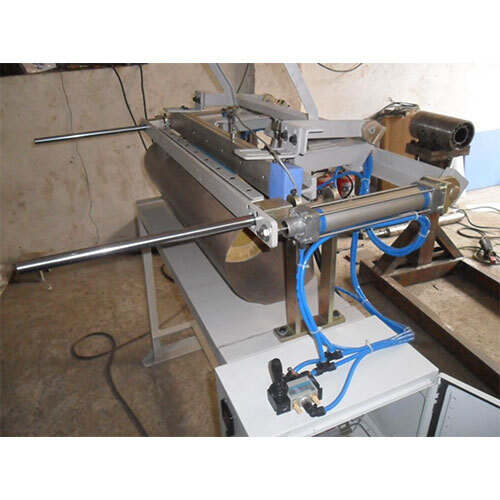

Edge sealing drying machine

Product Details:

- Machine Type Edge sealing drying machine

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Semi Automatic

- Surface Treatment Painted

- Color White,Blue

- Click to View more

X

Edge sealing drying machine Price And Quantity

- 1 Piece

Edge sealing drying machine Product Specifications

- Industrial

- 12 Months

- Electricity

- Semi-Automatic

- White,Blue

- Semi Automatic

- Painted

- Edge sealing drying machine

- 220 Volt (v)

Product Description

An Edge Sealing Drying Machine is a specialized machine used in industrial applications for drying and sealing the edges of materials, often used in the processing of certain products like paper, plastic, textiles, and laminates. The primary function of this machine is to apply heat or a sealing agent to the edges of materials to either seal or prevent fraying, thereby ensuring the materials integrity, durability, and aesthetics.

How an Edge Sealing Drying Machine Works:

-

Edge Sealing Process:

- Material Feeding: The material (e.g., fabric, plastic film, paper, or laminate) is fed through the machine.

- Heating: A heating element is used to apply heat to the edges of the material. In some cases, an adhesive or sealing agent is applied to the edges, followed by drying or curing using heat or UV light, depending on the material being processed.

- Sealing: After the edges are heated, they are either fused together or coated with a sealing agent that prevents the edges from unraveling or fraying. This is particularly useful for materials like fabrics or plastics, which are prone to edge damage.

- Drying: If an adhesive or sealing agent is applied, the drying or curing process follows to ensure that the sealing agent bonds properly, making the material ready for further use or packaging.

-

Temperature and Speed Control: The machine often includes adjustable settings for controlling the temperature and the speed at which the material moves through the machine. This allows for customization based on the type of material and desired sealing results.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese