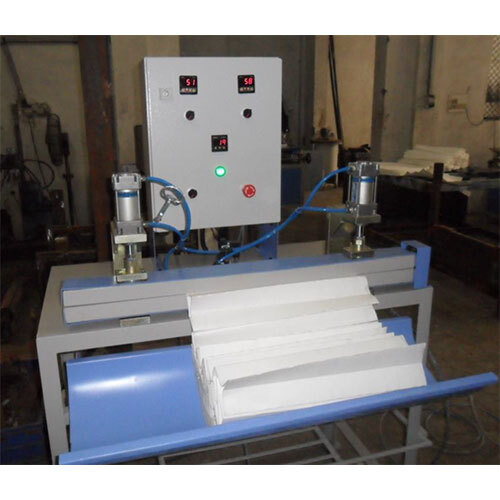

CIRCLE CUTTING MACHINE

Product Details:

- Control System Semi-Automatic

- Machine Type CIRCLE CUTTING MACHINE

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Green

- Click to View more

CIRCLE CUTTING MACHINE Price And Quantity

- 1 Piece

- 500000.0 INR/Piece

CIRCLE CUTTING MACHINE Product Specifications

- 220 Volt (v)

- Electricity

- Green

- Automatic

- CIRCLE CUTTING MACHINE

- Semi-Automatic

- Industrial

- Painted

CIRCLE CUTTING MACHINE Trade Information

- GURUGRAM

- 10 Piece Per Month

- 7 Days

- Contact us for information regarding our sample policy

Product Description

A circle cutting machine is a specialized tool designed for cutting precise circular shapes from various materials, such as metal, wood, plastic, rubber, or fabric. These machines are used across multiple industries for applications that require accurate and repeatable circular cuts. They come in various forms, from manual tools to fully automated systems, and are designed to handle a range of materials and thicknesses.

Types of Circle Cutting Machines:

-

Manual Circle Cutting Machines:

- Handheld Circle Cutters: Often used for materials like wood or plastic, these are simple, portable tools that can be used to cut circles of different sizes. They usually consist of a rotating blade attached to an adjustable arm, allowing the user to set the radius of the circle.

-

CNC Circle Cutting Machines:

- CNC Plasma Cutters: These machines use plasma torches to cut circles in metal sheets. A computer-controlled system precisely guides the torch along the cutting path to create accurate circular shapes.

- CNC Laser Cutters: Similar to CNC plasma cutters, but using laser technology to cut metal, wood, acrylic, and other materials with high precision.

- CNC Router Machines: Used for cutting circles in wood, plastics, or composites, CNC routers operate using a rotating bit that can be controlled by a computer to cut intricate and accurate circular shapes.

-

Rotary Cutting Machines:

- These machines use a rotating blade or wheel to cut through a material, especially for softer materials like fabrics, leather, or foam. The rotary blade moves along a circular track or is guided by a fixed radius, allowing consistent and smooth circular cuts.

-

Hydraulic or Pneumatic Circle Cutting Machines:

- Typically used in more industrial settings, these machines use hydraulic or pneumatic force to drive the cutting tool. They are often employed for thicker materials like metal or rubber.

Key Components of a Circle Cutting Machine:

-

Cutting Tool/Blade:

- The blade is the main component that performs the cutting. It could be a laser, plasma torch, rotary cutter, or mechanical blade, depending on the machine's type and the material being cut.

-

Adjustable Radius Mechanism:

- Many circle cutting machines have a feature that allows for the adjustment of the radius, so the operator can change the size of the circle being cut.

-

Guide Rail or Track:

- A rail or track helps guide the cutting tool or the workpiece to ensure that the cut is smooth and precise, especially in automated systems like CNC machines.

-

Drive Motor:

- In automated machines, a motor drives the movement of the cutting tool, or it powers the material feeding system, ensuring the cutting process happens efficiently.

-

Control System:

- In CNC machines, a computer or controller is used to program and control the cutting path, ensuring the circle is cut with high accuracy.

Applications of Circle Cutting Machines:

- Metal Fabrication: Cutting circular shapes out of metal sheets for use in machinery, automotive components, or structural supports.

- Woodworking: Creating precise circular shapes for furniture pieces, decorative items, or architectural components.

- Textile and Leather: Cutting out circles for patterns, patches, or accessories in the fashion and upholstery industries.

- Signage and Advertising: Producing round signs, logos, or promotional materials from various substrates like acrylic, foam, or plastic.

- Printing and Packaging: Cutting labels, packaging components, and other circular materials for commercial use.

Advantages of Using Circle Cutting Machines:

- Precision: These machines provide a high degree of accuracy, ensuring that the circles are uniform in size and shape.

- Efficiency: Automated systems, such as CNC machines, can cut large volumes of circles quickly and with minimal human intervention.

- Consistency: Automated circle cutting machines ensure each part produced has the same dimensions, which is essential for mass production.

- Versatility: Many machines can cut a variety of materials, allowing businesses to diversify their product offerings.

- Safety: These machines are typically equipped with safety features, like guards and emergency stop buttons, to protect the operator.

Common Features:

- Adjustable Speed and Pressure: Allowing for different materials and thicknesses to be cut efficiently.

- Multiple Cutting Heads: In larger machines, multiple cutting heads may be available to cut multiple parts at the same time.

- Software Integration: CNC-based circle cutters come with integrated software that helps create and modify cutting patterns.

Would you like more detailed information about any specific type of circle cutting machine or its applications?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese