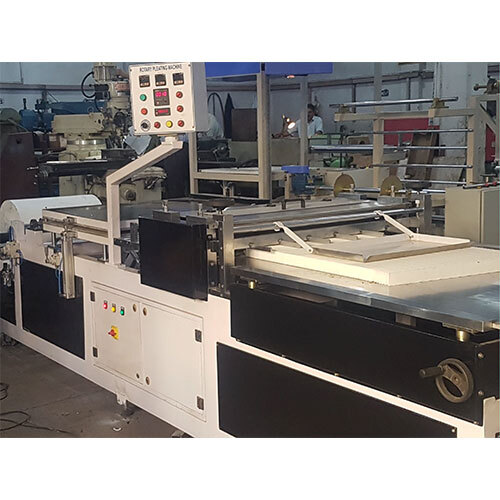

PNEUMATIC PRESS

270000 INR/Piece

Product Details:

- Control System Semi-Automatic

- Voltage 220 Volt (v)

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Silver

- Warranty 12 Months

- Click to View more

X

PNEUMATIC PRESS Price And Quantity

- 1 Piece

- 270000 INR/Piece

PNEUMATIC PRESS Product Specifications

- Industrial

- Painted

- 12 Months

- Silver

- 220 Volt (v)

- Automatic

- Semi-Automatic

- Electricity

PNEUMATIC PRESS Trade Information

- GURUGRAM

- 2-3 Piece Per Day

- 1 Days

- Contact us for information regarding our sample policy

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese