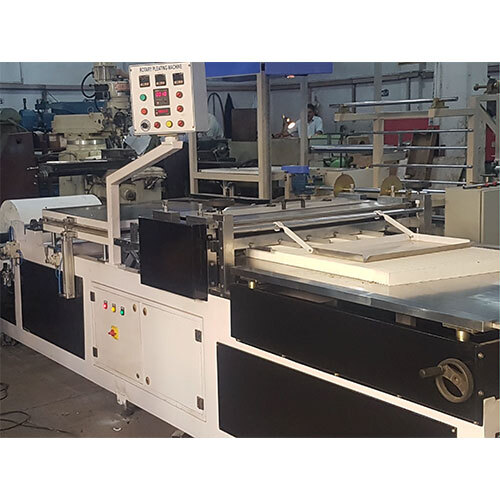

Rotary pleating machine

Product Details:

- Voltage 220 Volt (v)

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color White

- Warranty 1 Year

- Click to View more

Rotary pleating machine Price And Quantity

- 400000 INR/Piece

- 1 Piece

Rotary pleating machine Product Specifications

- White

- 1 Year

- 220 Volt (v)

- Painted

- Semi-Automatic

- Industrial

- Automatic

- Electricity

Rotary pleating machine Trade Information

- GURUGRAM

- 6 Piece Per Month

- 1 Week

- Contact us for information regarding our sample policy

Product Description

A Rotary Pleating Machine is a specialized piece of equipment used for creating pleats in materials like paper, nonwoven fabrics, and synthetic filter media. This machine is widely used in the manufacturing of filters (such as HEPA filters), air purifiers, HVAC systems, automotive filters, and even in packaging and decoration industries where pleated material is required.

The key feature of a rotary pleating machine is its ability to create precise, uniform pleats by using rotating mechanisms that fold the material in a consistent and controlled manner. The process typically results in an accordion-like structure, which increases the surface area of the material and enhances its filtration efficiency, or in other cases, its flexibility and cushioning.

Working Principle of Rotary Pleating Machine:

A rotary pleating machine works by feeding a material (usually paper, fabric, or synthetic media) through a set of rotating rollers that press and fold the material at regular intervals. These rollers create pleats with an even depth and spacing, giving the material its characteristic accordion-like appearance.

Key components involved in the pleating process include:

- Feed Rollers: These feed the material into the pleating area at a controlled speed.

- Rotating Pleating Rollers: These rollers rotate at a specified speed and force, pressing the material into uniform pleats. The rotating mechanism ensures a smooth and consistent pleating pattern.

- Drive Mechanism: The machine is powered by motors that control the speed and direction of the rollers, ensuring precise pleat formation.

- Cutting Mechanism: After pleating, some rotary pleating machines come with a cutting mechanism to trim the pleated material into the desired length.

Key Features of Rotary Pleating Machines:

-

High Precision Pleating:

- Rotary pleating machines are designed to create uniform pleats with consistent depth, spacing, and alignment. This precision is crucial for applications like filter production where uniform pleats directly affect the performance of the filter (such as airflow and filtration efficiency).

-

Adjustable Pleat Depth:

- Many rotary pleating machines allow operators to adjust the pleat depth according to specific requirements. This gives flexibility to manufacturers who need to create pleated media for different applications or specifications.

-

Continuous Feeding System:

- Rotary pleating machines generally feature an automated feeding system that continuously feeds the material into the machine, reducing manual labor and increasing the speed of production. The system often includes tension control to ensure the material moves smoothly through the pleating process without stretching or wrinkling.

-

Speed Control:

- Variable speed control allows the operator to adjust the pleating speed based on the type of material being used and the desired pleat density. This feature is critical for handling different materials, as softer or thicker materials may need slower speeds, while thinner materials may benefit from faster speeds.

-

Cutting and Shaping:

- Some rotary pleating machines are equipped with cutting units that can trim the pleated material to the required length once pleating is complete. This is useful for creating filter media or other products that require precise dimensions.

-

Minimal Waste:

- The design of rotary pleating machines minimizes material wastage by precisely measuring and feeding the material. This ensures that the pleated material is used efficiently, and excess material is minimized.

-

Integration with Other Systems:

- Rotary pleating machines can often be integrated into a complete production line that includes slitting, cutting, folding, and framing systems. This integration ensures that the pleating process is streamlined, and the final product is efficiently processed.

-

Material Versatility:

- Rotary pleating machines can handle a variety of materials including paper, nonwoven fabrics, synthetic media, and other flexible materials. This versatility makes the machine ideal for a wide range of industrial and consumer applications.

-

Edge Sealing (Optional):

- Some models come with the option to seal the edges of the pleated material using heat or adhesive. This is particularly useful when the material is used in filter applications where sealing prevents the pleats from opening up or fraying.

Applications of Rotary Pleating Machines:

-

HEPA Filter Manufacturing:

- Rotary pleating machines are commonly used to manufacture HEPA filters (High-Efficiency Particulate Air filters) by pleating paper or synthetic filter media. The pleated material increases the filter's surface area, improving its ability to trap fine particles in air and liquid filtration systems.

-

Air Purification and HVAC Systems:

- Rotary pleating machines are used to create pleated filter media for HVAC filters and air purifiers. These filters are designed to remove dust, pollutants, and allergens from the air in residential, commercial, and industrial spaces.

-

Automotive Filters:

- In the automotive industry, pleated filters are used in engine air filters, oil filters, and cabin air filters. The rotary pleating machine allows manufacturers to create the exact pleat design needed for these components.

-

Packaging Materials:

- In industries that require shock-absorbing or cushioning materials, rotary pleating machines can be used to create pleated packaging materials that protect products during transportation and storage.

-

Cleanroom Filtration:

- In cleanroom environments used for pharmaceutical, electronics, or food production, rotary pleating machines produce filters that maintain air quality by preventing contamination from particulate matter.

-

Craft and Decorative Items:

- In some creative industries, rotary pleating machines are used to produce pleated paper for decorative purposes, such as in scrapbooking, card making, and other craft applications.

Advantages of Rotary Pleating Machines:

-

High-Speed Production:

- Rotary pleating machines are designed for high-speed production, allowing manufacturers to produce large volumes of pleated material in a short time. This increases productivity and reduces manufacturing costs.

-

Consistency and Precision:

- The rotary mechanism ensures that pleats are consistently formed, providing uniformity in depth, spacing, and overall pleat structure. This is essential for applications where precision is critical, such as in air filtration.

-

Flexibility and Customization:

- With adjustable settings for pleat depth, speed, and cutting, the rotary pleating machine offers flexibility to meet different production requirements. This is especially important in industries like automotive, air filtration, and cleanroom filtration where custom specifications are often needed.

-

Reduced Labor and Automation:

- With automated feeding, pleating, and cutting systems, rotary pleating machines reduce the need for manual labor and improve overall process efficiency. This automation leads to faster turnaround times and less human error.

-

Material Efficiency:

- The precision of the rotary pleating process reduces waste, maximizing the use of materials and making the production process more cost-effective.

Conclusion:

A Rotary Pleating Machine is a versatile and essential piece of equipment used in the production of pleated materials, particularly in industries requiring high-precision pleating such as filter manufacturing, air purification, and automotive filtration. These machines ensure uniform pleats with precise depth, spacing, and alignment, while offering high-speed production capabilities and flexibility to handle various materials and applications.

If you need additional details or have specific questions regarding machine models, suppliers, or installation, feel free to ask!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese