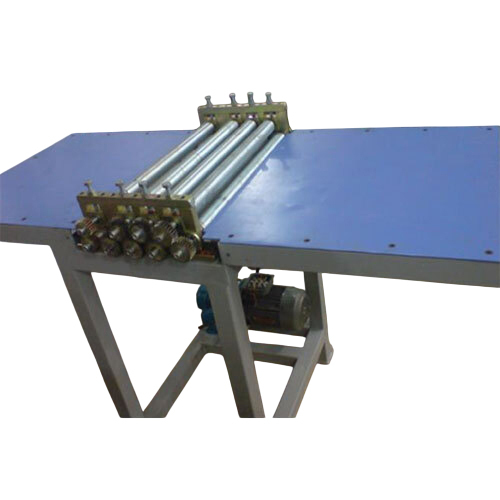

VULCANIZING PRESS MACHINE

Product Details:

- Control System Semi-Automatic

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Blue

- Warranty 12 Months

- Usage & Applications Industrial

- Click to View more

VULCANIZING PRESS MACHINE Price And Quantity

- 500000.0 INR/Piece

- 1 Piece

VULCANIZING PRESS MACHINE Product Specifications

- Painted

- 12 Months

- Electricity

- Semi-Automatic

- Industrial

- Blue

- Automatic

Product Description

A Vulcanizing Press Machine is a key piece of equipment used in the process of vulcanization, which is a chemical process that involves heating rubber (or similar materials) with sulfur to improve its strength, elasticity, and durability. This process is essential in the manufacturing of tires, rubber belts, hoses, gaskets, and other rubber products.

Key Components & Functions:

-

Heating Plates: The machine consists of two or more large metal plates that are heated to a specific temperature. These plates are where the rubber products are placed for vulcanization. The plates press against the rubber to apply both heat and pressure.

-

Pressure Mechanism: The press machine applies pressure to the rubber, which helps to shape the material and enables the sulfur to crosslink the rubber molecules. This ensures the rubber becomes more resilient and less prone to wear, aging, and environmental damage.

-

Control System: Vulcanizing press machines are equipped with advanced controls to regulate both the temperature and pressure applied during the vulcanization process. This is crucial because both the temperature and time must be precisely controlled to achieve the desired properties of the final rubber product.

-

Mold: In many applications, the press machine includes molds to shape the rubber into a specific form or product. For example, when producing rubber tires, molds are used to shape the rubber into tire treads.

Types of Vulcanizing Press Machines:

-

Hydraulic Vulcanizing Press: Uses hydraulic pressure to press the rubber between heated plates. This is one of the most common types and is often used for large-scale production of rubber products.

-

Mechanical Vulcanizing Press: Uses mechanical force, often driven by a motor, to apply pressure to the rubber. These are typically used for smaller items or lower-volume production.

-

Vacuum Vulcanizing Press: Used when a vacuum is required during vulcanization to prevent air bubbles or to achieve a specific density in the rubber product.

-

Rotary Vulcanizing Press: The rubber product or mold rotates as the heat and pressure are applied, ensuring an even vulcanization process for products that require uniformity, such as rubber hoses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese